Reduce Your Risk and Increase Your ROI with Machine Tool Maintenance Training

ELK GROVE VILLAGE, IL, April 5, 2021

Whether your business is a large operation or runs on a smaller scale, the machine tools you have invested in play a large part in your success. The breakdown of a machine because of improper maintenance is the last thing you want to have happen- not only because it can be costly, but also because it likely could have been prevented.

Making sure your team performs the proper maintenance and understands how to best troubleshoot when issues arise will not only keep your machine tool running longer, but can prevent those unexpected and expensive repairs.

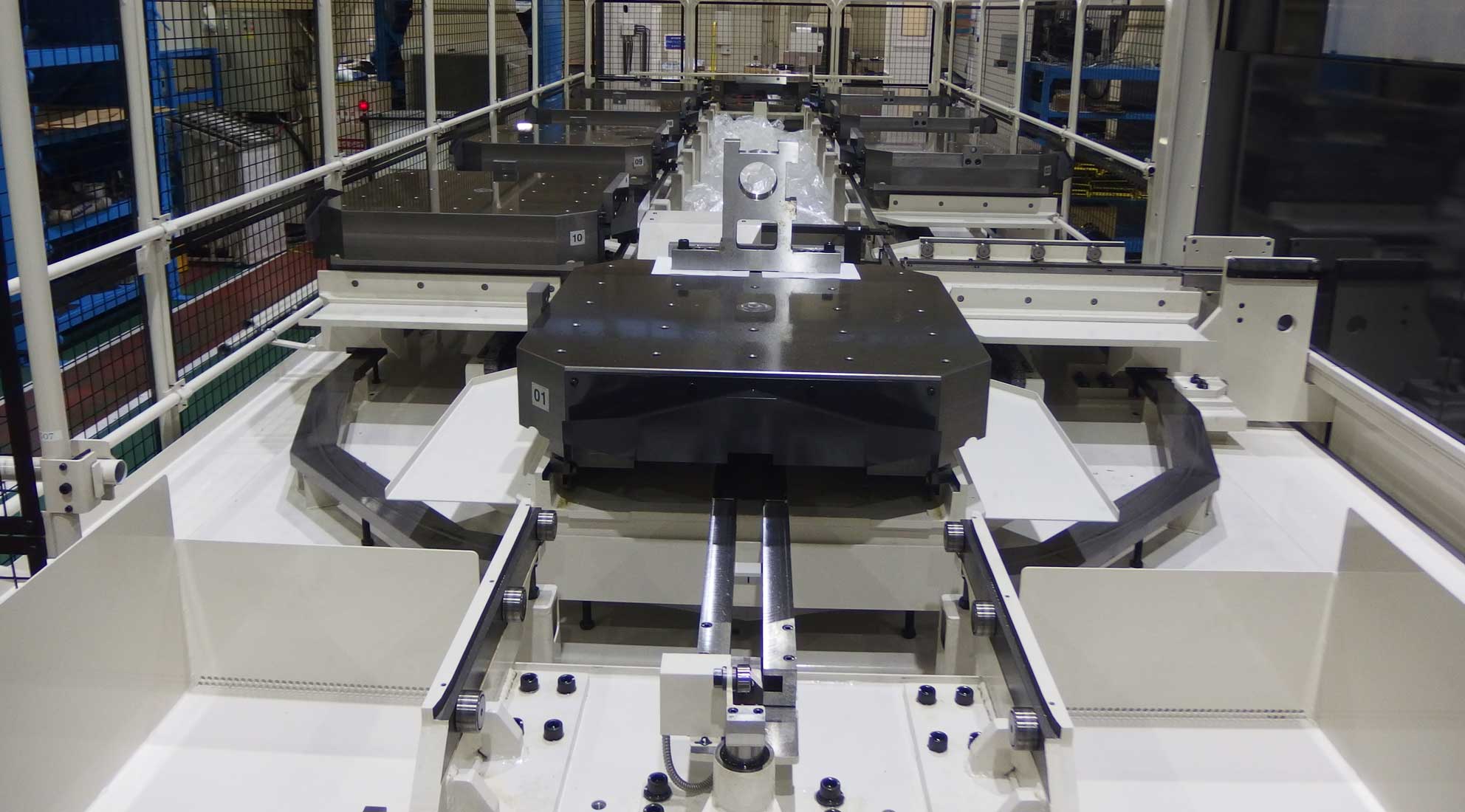

Shibaura Machine is committed to helping our customers extend the life of their machine tools. From horizontal boring machines, vertical turning lathes, bridge mills, and horizontal machining centers we provide a curriculum on maintenance training for all our machine tools that is straightforward and easy for your team to immediately start implementing.

Maintenance Training Made Easy

Whether you are in the medical, semiconductor, mining and construction, aerospace or automobile industry, the benefits of maintenance training are the same. Having a team that is able to conduct proper maintenance on all fronts allows the machine tool efficiencies, product quality improvements, and overall greater ROI on your machine investment.

Shibaura Machine has broken down maintenance training for our machine tool owners into three easy to understand and implement sections.

1. Troubleshooting Maintenance

This training offers a thorough review of the maintenance manuals on how to use and locate the information necessary to troubleshoot.

2. Safety Maintenance

Upon completion of this training, students will understand and be able to easily locate interlocks and emergency switches.

3. Preventative maintenance

Often overlooked, but perhaps the most important is preventative maintenance. This training includes showing the location of oil charts, oil locations, filter, and additional lubrication points in order to service the machine tool properly.

Machine Tool Maintenance Training

When it comes to proper maintenance and upkeep of your machine tool, our team is committed to helping you succeed. Contact our team to discuss machine tool maintenance training for your factory.

Contact our Machine Tool team to learn more and register for training courses.

Related Articles

Machine Tool Reliability- An Important Factor in the Manufacturing Process

ELK GROVE VILLAGE, IL, March 23, 2021 - When a machine tool fails it not only challenges due date commitments, but can lead to poor quality workpieces, slower production output, and downtime losses. Bottom line, if your machine tool isn’t reliable; it will...

Read moreMaximize Speed and Maintain Control with Tosnuc CNC Shape feature

ELK GROVE VILLAGE, IL, March 1, 2021 - When purchasing a new CNC Machine Tool many customers find themselves still not being able to machine complex workpieces as fast as needed due to inconsistent feedrates or tool chip loads. Shibaura Machine has now de...

Read moreDoes Your Machine Tool Offer True Auxiliary Equipment integration? Why It’s important.

ELK GROVE VILLAGE, IL, February 23, 2021 At the end of the day, machine tools are meant to help people make things. In today’s challenging economic climate many of us are looking to make things quicker, with less energy, and hurdles. Accomplishing this me...

Read moreHow a Tool Probing System Impacts Your Manufacturing Performance and Profitability

ELK GROVE VILLAGE, IL, February 17, 2021 Have you ever heard the saying time is the most valuable commodity? On the factory floor that couldn’t be more true, time is indeed money. In order to make the best use of time, many manufacturers are continually l...

Read moreMaking Complex Simplified with Shibaura Machine CNC Machine Tools

ELK GROVE VILLAGE, IL, February 9, 2021 Simple operator controls and easy to use machines have become essential on shop floors in order to stay competitive. All around ease of use helps manufacturing operations set up jobs faster and even more accurately,...

Read moreHow Quick Change Tooling Can Boost Profits in 2021

ELK GROVE VILLAGE, IL, January 18, 2021 Tool changes in machine operations can take time. But what if you could shave just a few seconds, imagine even minutes off of this process? In a large volume machine operation, this could add up to hundreds of thous...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools