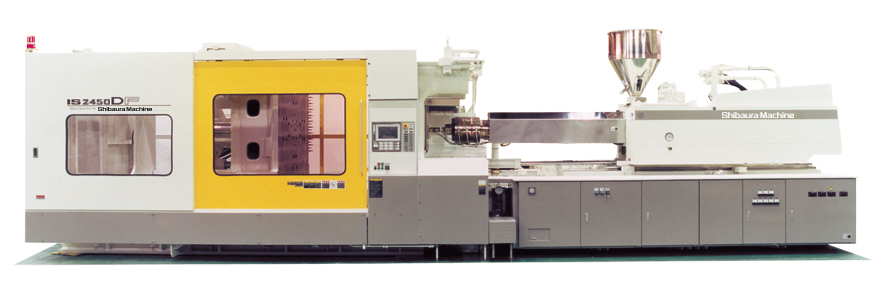

ISF2200D

Hydraulic ISG-D/ISF-D Machine

The ISG-D & ISF-D Series hydraulic machines have been specifically designed for the molding of large sized parts. This series is equipped with a unique, two-platen, direct lock clamping device. While offering the same stroke as conventional designs, this compact design delivers faster cycling speeds and a smaller machine footprint requiring significantly less floor space.

Tonnage - Metric (Metric Tons)

Tie Bar Distance (HxV) - Metric (mm) 7

Platen Dimensions (HxV) - Metric (mm)

Injection Capacity (PS) - Metric (g)

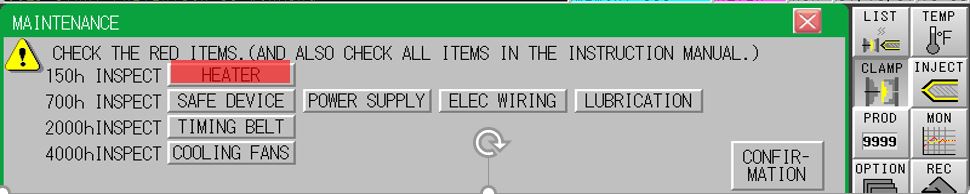

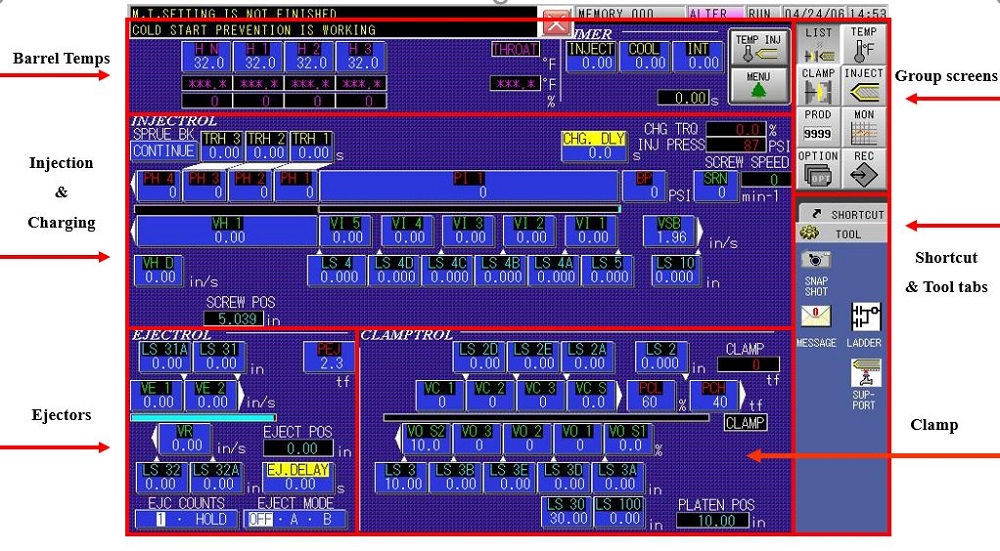

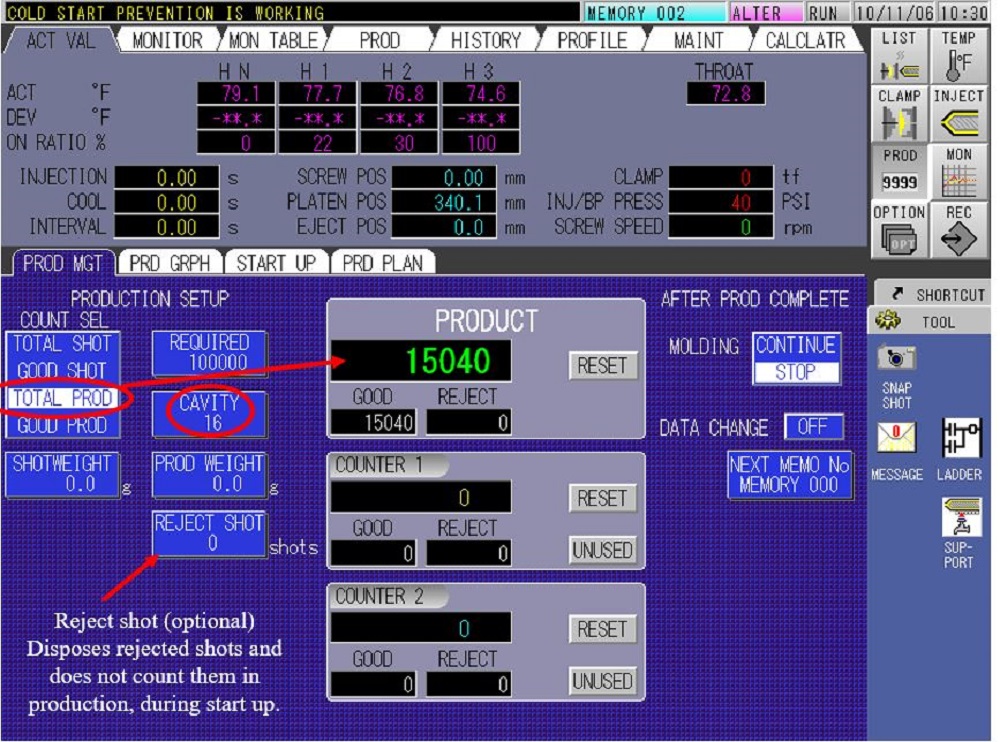

Injectvisor V50 Controller

Shibaura Machine's V50 controller uses real-time input to report molding conditions and make adjustments as needed, resulting in greater part repeatability and fewer rejects. The 15" touchscreen is intuitive and easy to use, shortening the learning curve while improving accuracy and productivity.

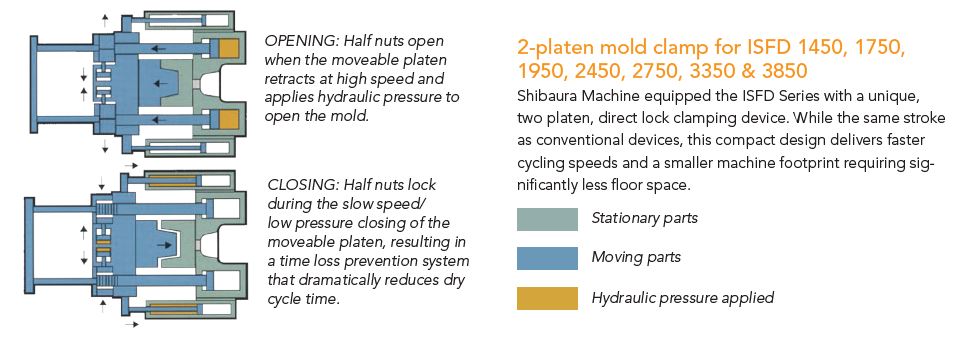

Space saving, two platen clamp design

Our ISG-D / ISF-D series features a unique two-platen, direct lock clamping device. While offering the same stroke as conventional designs, this compact design delivers fast cycling speeds and a smaller machine footprint requiring significantly less floor space.

3 micron filtration of hydraulic oil

Hydraulic oil is continuously cycled through three micron filters, increasing oil life while reducing machine malfunctions, maintenance and downtime.

MOLDLYZER - Quality Control System

MOLDLYZER is a patented quality control program that helps ensure part-to-part repeatability for any size production run. MOLDLYZER continuously samples actual hydraulic pressure at different checkpoints during injection, and compares the data to an injection pressure model curve established by the operator for an acceptable part. Data is displayed on the V50 controller, providing the operator with visual indication of molding performance.

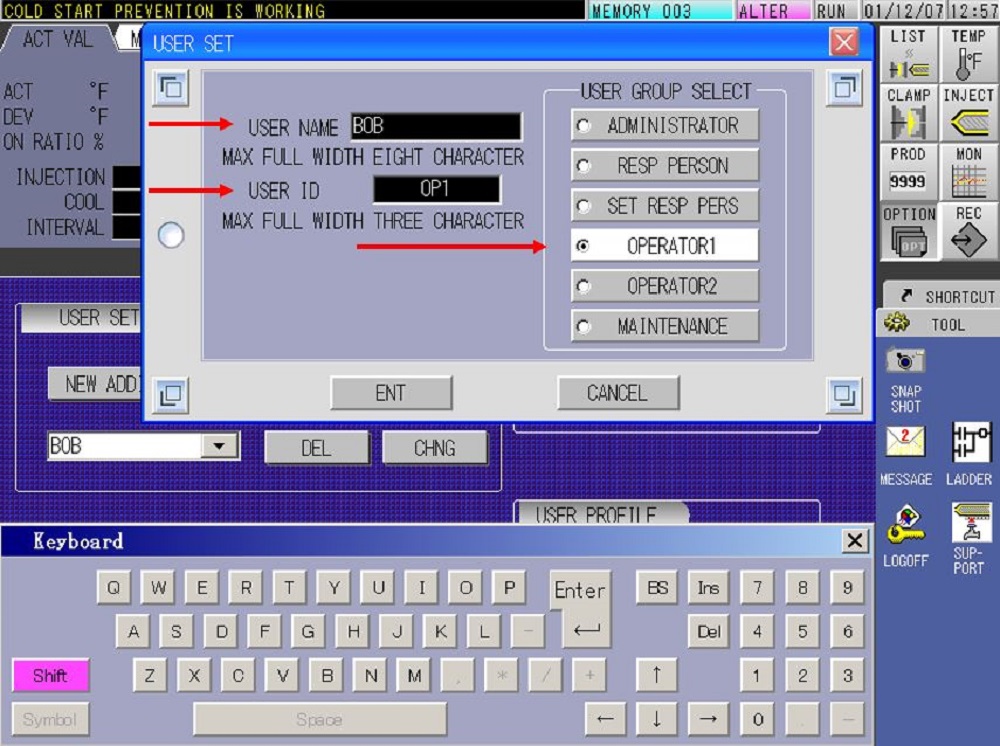

User Log-in / Access Control

Easily set permission levels for machine operators, maintenance personnel, production managers, administration and more. By requiring users to log in, you can easily see the changes made to your process, who made the changes, and when the changes were made.

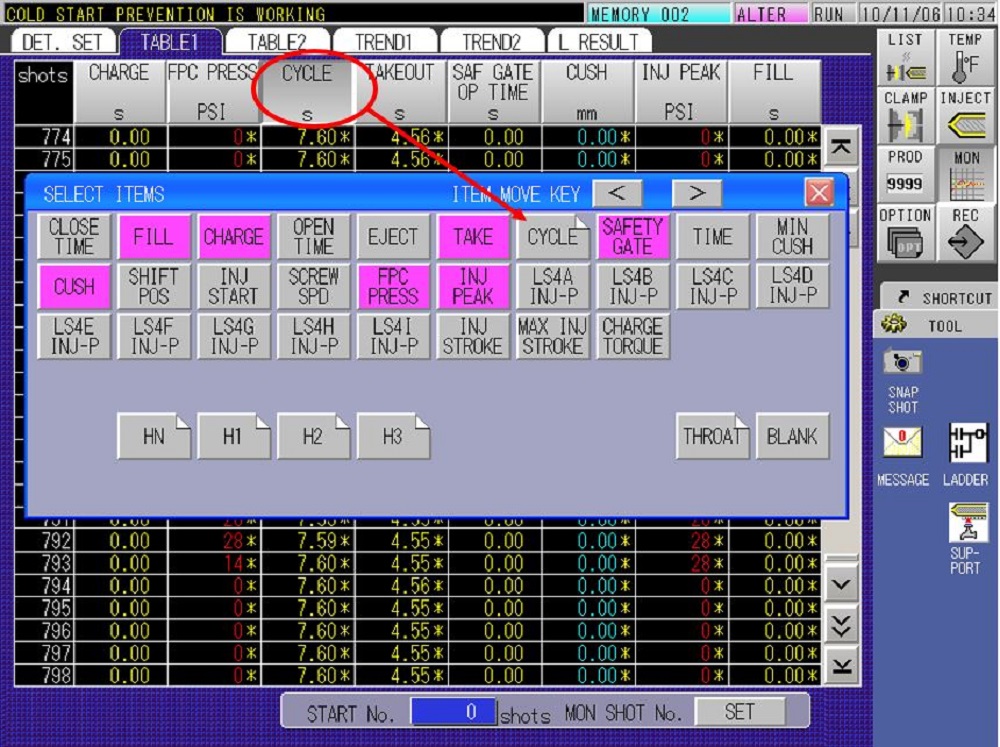

Process Monitoring

Monitor up to 16 processing parameters. You can easily set tolerances around those items and signal an alarm if any of the items move outside of the allowable processing window. Trend charts and SPC/SQC functions are included.

History

The history screen shows the last set-up changes that were made along with alarms, and machine stoppages. This allows you to see what changes were made to the process, by whom, and at what time.

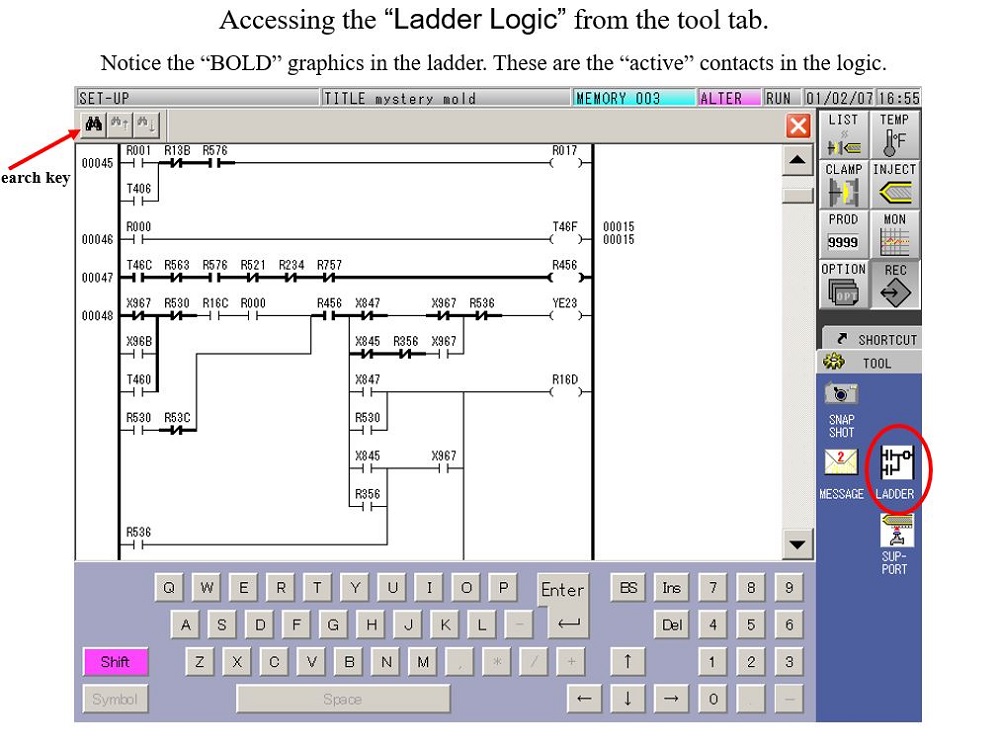

Accessible Machine Ladder Logic

The user has access to the machine ladder logic. This allows the user to see what inputs and outputs are active in real time.

Storage of up to 300 mold recipes

The V50 controller provides storage for up to 300 mold recipes. Notes and pictures can be stored along with the set-up data giving operators more information about the process they are setting up.

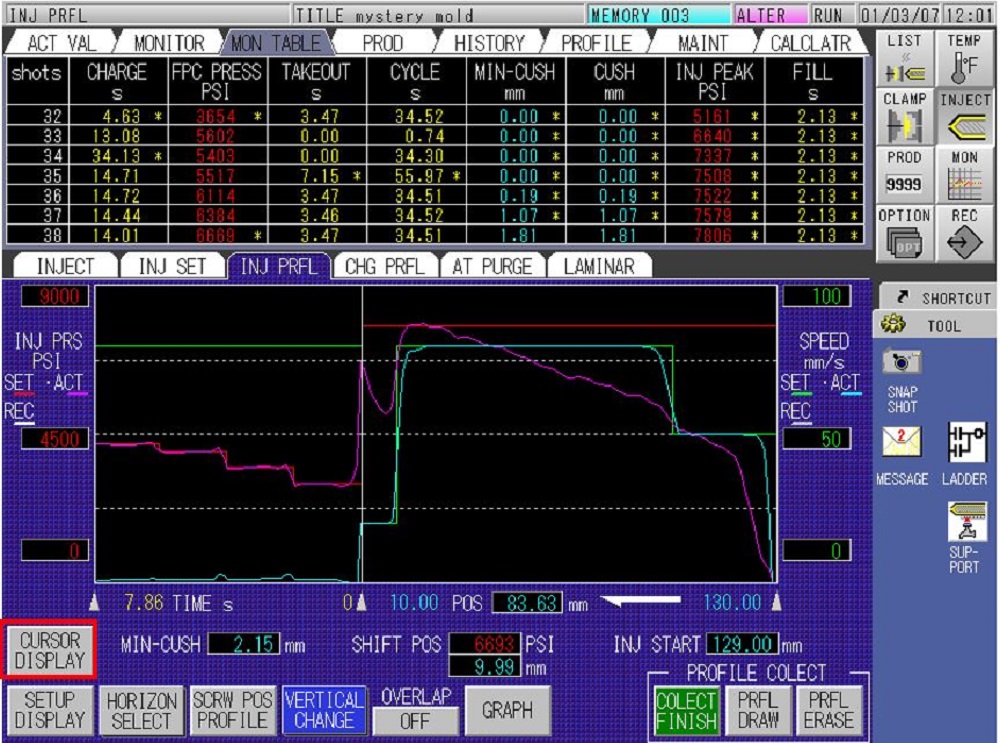

Injection Profile Graph

Real time graphic representation of the injection process showing pressure and speed during both injection and holding. This can be set to refresh each shot or to overlay, allowing the operator to easily see variations. This can be especially useful during process set-up.